In global apparel sourcing, knitted embroidered fabric occupies a strategic middle ground—where comfort meets ornamentation, and scalability meets design identity. Unlike woven embroidery, knitted bases bring stretch, drape, and body adaptability, making them ideal for modern fashion systems driven by lifestyle wear, occasionwear, and hybrid silhouettes.

Across international buying hubs—Europe, the Middle East, North America, and emerging Asian markets—buyers are no longer sourcing “fabric” alone. They are sourcing manufacturing reliability, design repeatability, and export-grade consistency. This is where bulk-only knitted embroidery production combined with digital printing becomes commercially powerful.

Knitted Embroidered & Printed Fabrics for Global Export Markets

From India’s manufacturing ecosystem—especially Surat’s knit processing clusters—this category feeds global garment brands, exporters, and importers looking for volume stability rather than experimental yardage.

Fabric Characteristics Admired by Global Buyers

Knitted embroidered fabrics are appreciated globally for three core attributes:

- Wearability: Breathability, stretch recovery, and softness — critical in warm climates and all-day wear.

- Surface Richness: Embroidery adds perceived value without compromising movement.

- Production Efficiency: Knits accept embroidery and digital prints with faster turnaround than complex woven bases.

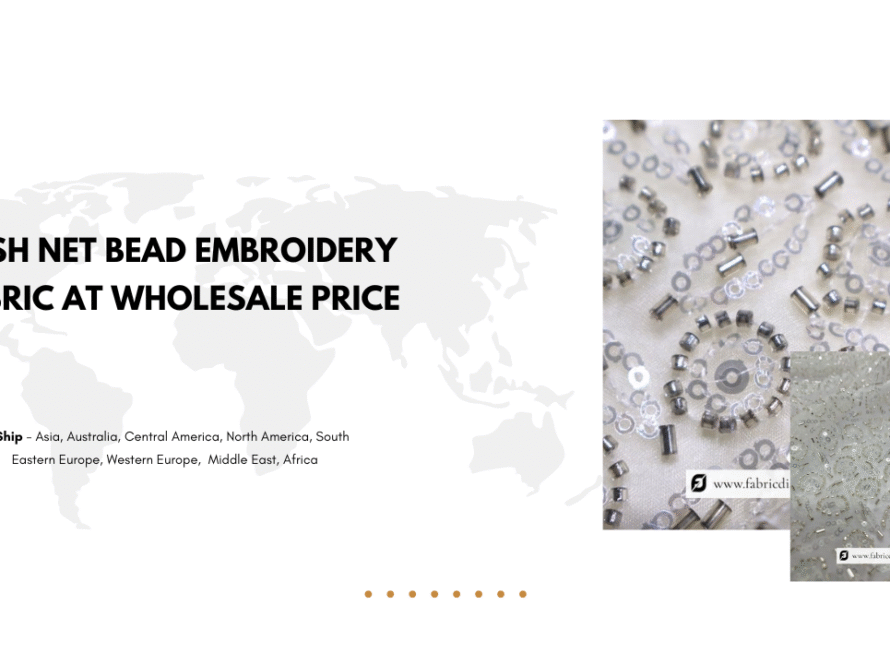

Typical technical specs demanded by buyers include:

- GSM: 160–280 depending on category

- Yarn Types: Polyester filament, viscose blends, cotton-poly knits

- Embroidery Density: Medium to high stitch count optimized for drape

- Stitch Types: Chain stitch, satin stitch, running stitch, computerized motifs

- Machines: Multi-head embroidery machines with automated tension control

- QC Standards: Shrinkage control, colorfastness, needle damage inspection

These factors directly influence sourcing decisions on platforms like Alibaba, IndiaMART, and TradeIndia.

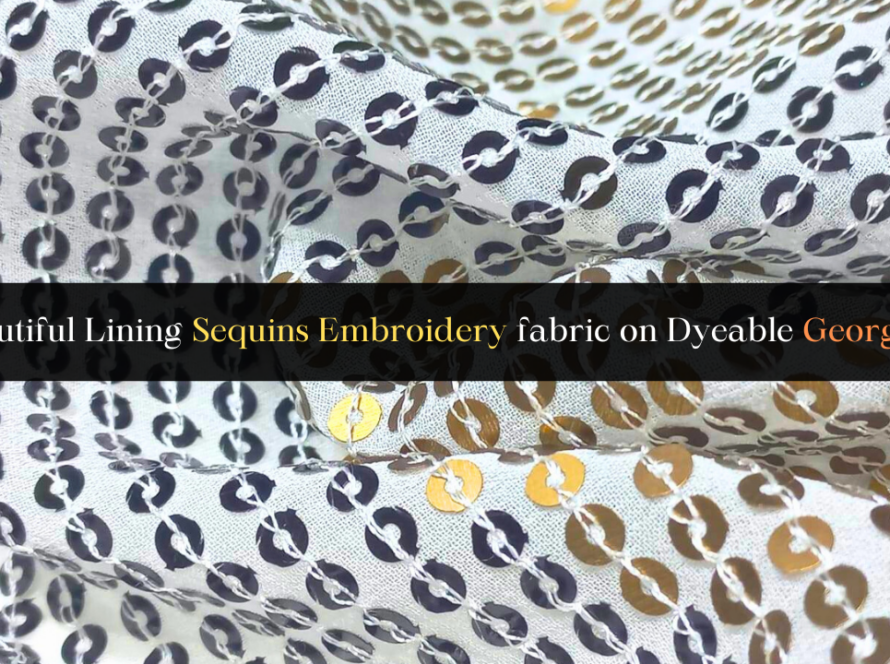

Fabric Variations & Fashion Influence

Globally traded knitted embroidered fabrics often appear in variations such as:

- All-over embroidered knits

- Panel-placement embroidery for garment cutting efficiency

- Digitally printed knit bases with post-embroidery enhancement

- Mono-color embroidery for minimalist Western brands

- Dense ornamental patterns for Middle Eastern aesthetics

Fashion forecasting agencies like WGSN and Business of Fashion (BOF) consistently highlight textured knits as high-conversion materials due to their adaptability across categories.

Global Demand & Country-Specific Buying Trends

International demand for embroidered knits is driven by:

- Athleisure-meets-occasionwear trends

- Modest fashion expansion

- Fast-response capsule collections

Indian psychology contributes roughly 30% to this demand—where embroidered knits are tied to festive, semi-formal, and bridal fusion wear. The remaining 70% demand is export-led, driven by structured buying calendars, repeat programs, and compliance-driven sourcing.

According to Statista and Fibre2Fashion, knitted fabric exports with value addition outperform plain knits in margins and repeat orders.

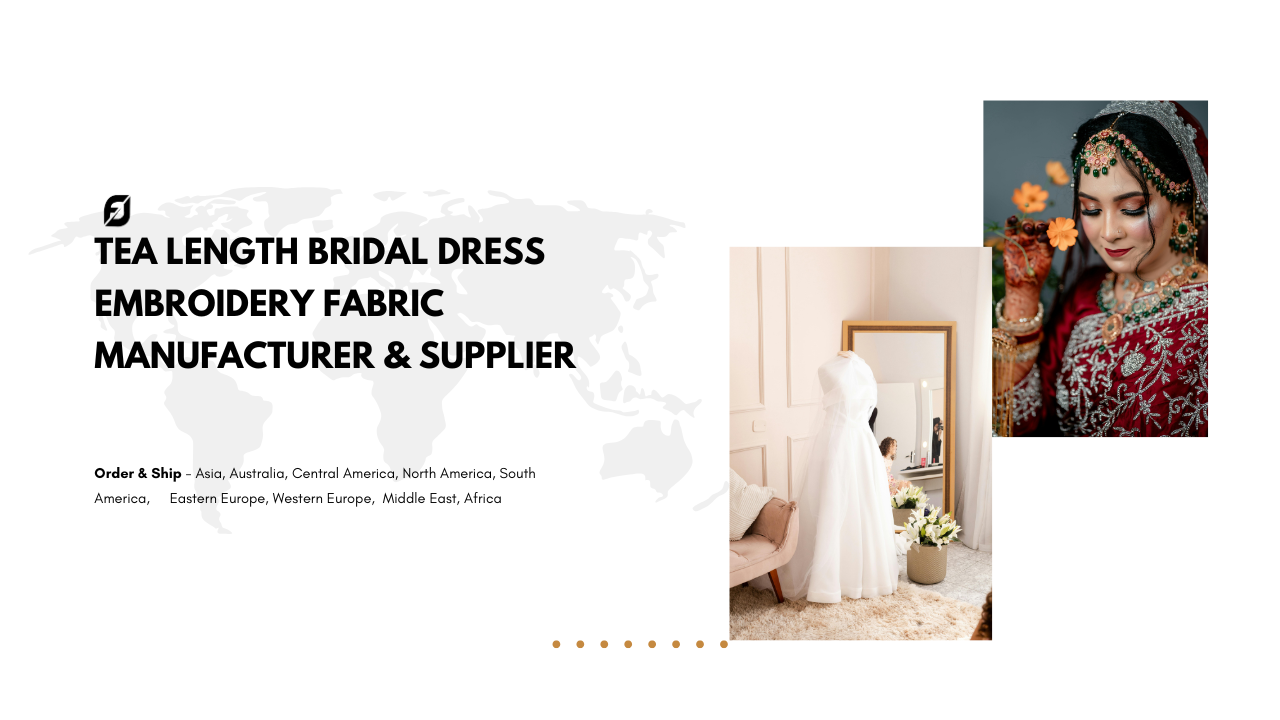

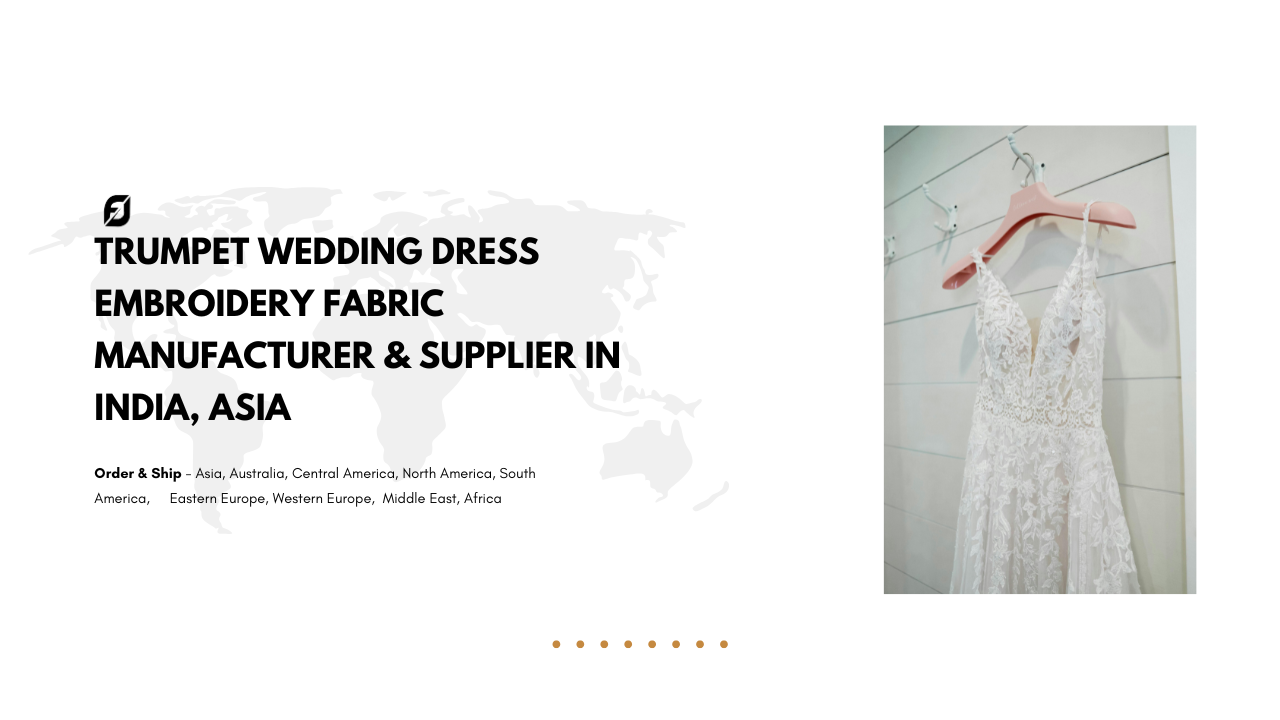

Bridal Relevance Across Cultures

While bridal usage varies globally, embroidered knits play a role in:

- Bridal trousseau layering

- Reception outfits

- Engagement and pre-wedding functions

In India, these fabrics appear in lehenga blouses, dupattas, and indo-western gowns. Internationally, they translate into:

- Modest bridal gowns

- Evening bridal dresses

- Luxe loungewear for wedding weeks

Publications like Vogue and Harper’s Bazaar increasingly document comfort-centric bridal fashion, validating this category’s relevance.

Wedding Wear Applications & Local Outfit Names

Knitted embroidered fabrics are used in:

- Kaftans (Middle East)

- Occasion dresses (Europe & US)

- Kurti sets and anarkali tops (India)

- Co-ord sets for wedding festivities

Buyers value these fabrics because they allow embroidery richness without the stiffness of woven bridal textiles.

Partywear & Eveningwear Demand

Partywear buyers prioritize:

- Lightweight shine

- Movement

- Skin comfort

Digitally printed knitted bases with embroidery overlays are especially popular for evening collections. Designers influenced by Parsons, FIT, and Istituto Marangoni often specify knitted embroidery for experimental silhouettes.

Garment Manufacturing Usage

Garment factories prefer embroidered knits because:

- Reduced cutting wastage

- Faster sewing cycles

- Lower rejection rates

Brands supplying to department stores and online marketplaces (Amazon Business, Etsy private labels) consistently reorder such fabrics in bulk once quality stabilizes.

Designer & Boutique Preferences

Boutique designers prefer:

- Consistent embroidery repeat

- Color-controlled digital printing

- Custom motif scalability

Sampling often begins with smaller quantities, but final production always shifts to bulk manufacturing partners capable of meeting timelines.

B2B Sourcing Behavior & Import Logic

Importers typically look for:

- One reliable manufacturer

- Predictable MOQ structures

- Clear HS codes & export documentation

- Stable pricing across seasons

Common problems include shade variation, embroidery thread breakage, and shipment delays—solved through vertically integrated production and pre-shipment QC.

Custom Manufacturing, MOQ & Export Reliability

Bulk buyers expect:

- Custom embroidery programs

- Digital print alignment

- Defined MOQ (usually 300–1000 meters/design)

- Export-grade packing

This is where factory-based suppliers outperform traders.

Why FabricDiary & Madhav Fashion Fit Global Buyers

FabricDiary functions as a sampling and discovery platform—supporting:

- Small quantities

- Designer testing

- Global swatch shipping

Madhav Fashion (Surat) operates as a bulk manufacturing backbone:

- Factory pricing

- High-volume embroidery capacity

- Digital print integration

- Export documentation support

Together, they serve both ends of the sourcing journey—without aggressive selling.