Over the last decade, global garment brands have quietly begun reassessing one of the most critical decisions in their supply chain: where their fabrics come from (Fabric Sourcing). While China once dominated textile sourcing almost unquestioned, today a growing number of apparel brands, buying houses, and fashion manufacturers are diversifying — and increasingly looking toward India.

This shift is not driven by cost alone. It is shaped by buyer psychology, geopolitical risk, design flexibility, cultural compatibility, and long-term supply security. Publications like Forbes, Business Insider, and The Business of Fashion have repeatedly highlighted how sourcing strategies are evolving beyond single-country dependence.

Why Global Garment Brands Are Shifting Fabric Sourcing from China to India

Fabric Sourcing Psychology: How Global Buyers Think Today

Modern B2B buyers are no longer chasing the cheapest roll of fabric. Instead, they prioritize:

- Supply continuity

- Customization ability

- Ethical manufacturing

- Communication reliability

- Cultural alignment with fashion sensibilities

Indian fabric suppliers increasingly appeal to this mindset. Unlike transactional sourcing, India offers relationship-driven manufacturing, something global brands value deeply — especially boutique labels, premium designers, and mid-scale apparel brands.

Fabric Characteristics That Global Buyers Admire in Indian Textiles

Indian fabrics are appreciated not just for aesthetics but for engineering depth. Buyers often cite:

- Balanced GSM ranges suitable for both summer and all-season garments

- Strong yarn integrity (cotton, viscose, polyester blends)

- Dense yet breathable embroidery constructions

- Consistent colorfastness for export climates

From lightweight voile to heavy embroidered bases, Indian mills combine handcraft heritage with industrial precision — a rare mix in global textile manufacturing (Fabric Sourcing).

Intricate threads & premium texture Printed Fabric

Creative, colorful & always trending Position Printed Fabric

Perfect alignment for standout looks Jacquard Fabric

Rich textures with woven luxury Plain Dyeable (RFD)

Customize colors, your way Pure Dyed Fabrics

Ready-to-stitch brilliance Designer Dupattas

From shimmer to sheer elegance Ready Stocks

Quick ship fabrics in bulk Kurti Fabrics

Comfort meets tradition New Arrivals

Fresh drops, every week

Fabric Variations Shaped by Fashion & Function

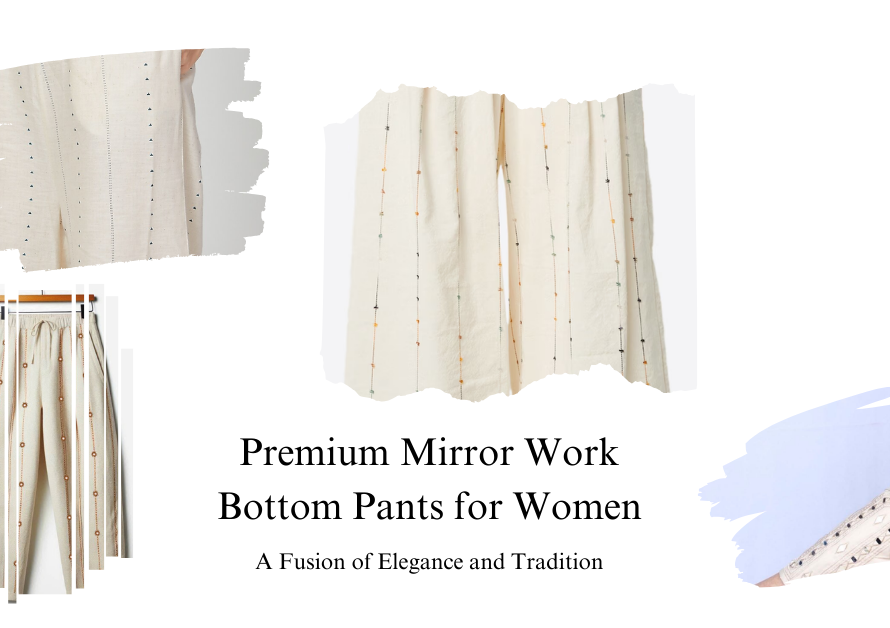

India’s strength lies in variation at scale. Unlike standardized production models, Indian suppliers offer:

- Embroidery (schiffli, zari, sequin, mirror)

- Printed bases (digital, reactive, pigment)

- Jacquards, plains, and dyeable fabrics

These variations allow global brands to align collections with regional fashion cues — whether minimal Scandinavian silhouettes or ornate Middle Eastern aesthetics.

Global Demand Trends: Why India Fits the New Equation

According to industry data referenced by Statista and Fibre2Fashion, buyers increasingly demand:

- Shorter lead times

- Flexible MOQs

- Seasonal experimentation

India’s decentralized textile ecosystem supports this perfectly. From Surat’s embroidery clusters to South India’s weaving hubs, brands can source multiple fabric categories without changing countries — a strategic advantage over China’s centralized model.

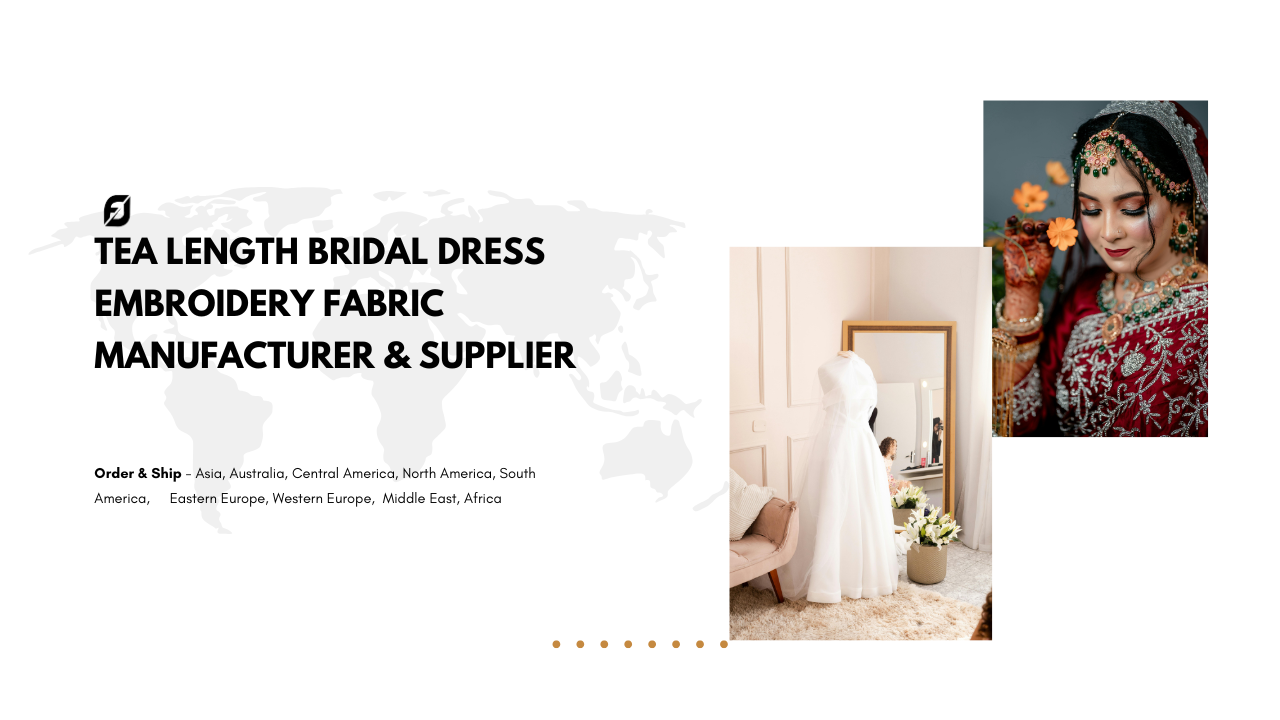

Bridal Wear Influence: A Global Fashion Constant

Bridal and ceremonial wear continues to be a high-margin segment globally — from South Asian weddings to Middle Eastern festivities and Western couture capsules.

Indian embroidery fabrics, known for:

- High stitch density

- Zari and thread detailing

- Layered textures

are frequently chosen for bridal lehengas, gowns, kaftans, and couture ensembles — a fact often highlighted in Vogue and Harper’s Bazaar runway analyses.

Wedding Wear Applications Across Cultures

Different markets interpret wedding fashion uniquely:

- South Asia: lehengas, anarkalis, dupattas

- Middle East: abayas, kaftans

- Europe & US: occasion gowns, couture separates

Indian fabrics adapt effortlessly across these formats, offering design flexibility without reengineering production, something buying houses appreciate deeply.

Partywear & Eveningwear: Where India Excels

Eveningwear demands drama — sequins, shimmer, fluid drape. Indian embroidery and embellished fabrics dominate this category, often seen in:

- Resort wear collections

- Red-carpet inspired partywear

- Boutique capsule lines

Fashion schools like Parsons and NIFT frequently study Indian embellishment techniques for their adaptability across silhouettes.

Garment Manufacturing Usage: From Boutique to Factory Floors

Indian fabrics are now integral to:

- Private label manufacturing

- Mid-size global garment factories

- Designer-led production houses

Brands sourcing from platforms like Alibaba, IndiaMART, TradeIndia, and Amazon Business increasingly shortlist Indian suppliers for sampling-first, scale-later strategies.

Designers & Boutiques: A Preference for Indian Fabric Houses

Designers value:

- Sampling flexibility

- Custom embroidery placements

- Small-batch experimentation

Indian suppliers support this creative process far better than rigid bulk-only systems, making India a natural partner for emerging and established designers alike.

B2B Sourcing Behavior: How Importers Actually Buy

Real-world importer behavior involves:

- Trial orders

- Swatch approvals

- Incremental scaling

- QC audits

India’s openness to small beginnings and long-term partnerships aligns perfectly with this purchasing psychology.

Custom Manufacturing, MOQ & Reliability

Indian manufacturers increasingly offer:

- Low to mid MOQs

- Custom embroidery & printing

- Export-compliant QC standards

Reliability markers like consistent GSM, repeat color accuracy, and shipment discipline have significantly improved — making India a serious long-term sourcing hub.

Why FabricDiary & Madhav Fashion Fit This Global Shift

For global buyers navigating this transition:

- FabricDiary supports designers, boutiques, and sampling teams with small quantities, swatches, and global shipping.

- Madhav Fashion (Surat) serves bulk buyers with factory pricing, scalable production, and export-ready manufacturing.

Both represent different ends of the same sourcing spectrum — flexibility at the start, reliability at scale.

———————

FAQs

1. Can international buyers source small quantities from India?

Yes, platforms like FabricDiary allow sampling and small-batch sourcing before bulk commitments.

2. What is the typical MOQ for Indian fabric exporters?

MOQs vary, but many suppliers now support flexible minimums depending on fabric type.

3. How long does fabric shipping from India take?

Typically 5–12 business days internationally, depending on destination and order size.

4. Are Indian fabrics compliant with global quality standards?

Most export-focused manufacturers follow strict QC, including colorfastness and GSM checks.

5. Can buyers request custom embroidery or prints?

Yes, customization is one of India’s strongest sourcing advantages.

6. What payment methods are commonly accepted?

Wire transfer, LC, and sometimes online payment gateways for smaller orders.

7. Is India suitable for long-term sourcing partnerships?

Absolutely — many global brands now maintain multi-year sourcing relationships in India.